Requirements for optical film slitting machine

1. Core performance requirements of optical film slitting machine

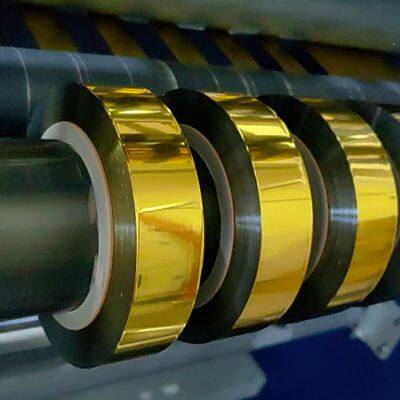

1. Slitting accuracy: Optical films are used in high-end fields such as displays and lenses, and the slitting accuracy needs to reach ±0.05mm (according to ISO 9001 standard), and the edge burr ≤ 20μm. For example, a material supplier requires a radial runout of 0.01mm for the slitting machine shaft to ≤ensure that ultra-thin films (such as 50μm thick PET) are damage-free.

2. Material compatibility: It needs to be adapted to a variety of optical films, including PET (polyester), COP (cyclic olefin polymer), and PC (polycarbonate), with a thickness range of 5-500μm. Special coating films (such as anti-glare AG film) require the slitting machine to be equipped with anti-scratch guide rollers.

3. Tension control: Closed-loop servo system is adopted, and the tension fluctuation is controlled within ±1% (refer to the "JB/T 10920-2020 Industry Standard for Slitting Machines") to avoid tensile deformation of the film.

2. Equipment functions and operating standards

1. Automation Capabilities:

◦ Automatic Correction System: Correction accuracy ± 0.3mm, response time <0.1 seconds (such as BST Group's EPC-3000 system).

◦ Intelligent detection: equipped with CCD camera to detect defects on the film surface, identifying defects with an accuracy of 0.1mm².

2. Stability Requirements:

◦ Continuous operation for 24 hours temperature drift ≤± 1°C, humidity adaptability 30%-80%RH (according to GB/T 2423 industrial environment test standard).

3. Environmental Protection and Safety:

◦ Noise ≤ 75dB (measured 1 meter away from the device);

◦ Scrap recycling rate ≥ 95%, in line with EU RoHS directive.

3. Selection and expansion suggestions

1. Blade material: The service life of carbide knives is 3 times that of ordinary steel knives (about 5000 kilometers of film material).

2. Maintenance intervals: Lubrication of critical components (e.g. bearings) is carried out every 500 hours, with a tool change interval of 200 hours (according to 3M technical white paper).

(Note: The above parameters are from the technical manuals and international standards of leading enterprises in the industry, and users can adjust them according to actual production needs.) )

Recently Posted

-

How to reduce material waste in slitting machines through parameter optimization?

October 31, 2025Reducing material waste in slitting machines through parameter optimization is a systematic project that involves multiple aspects Read More

Read More -

Slitting machine blade life extension: parameter setting and maintenance tips

October 31, 2025Extending blade life is a systematic project that involves multiple aspects such as parameter setting, daily maintenance, equipmen Read More

Read More -

From manual to automated – a factory's path to a carbon belt slitting upgrade

October 31, 2025Behind label printing technology lies a seemingly inconspicuous yet crucial component – ribbons. It is the "ink" of ther Read More

Read More -

Behind the growth of the ribbon slitting machine market: downstream demand-driven analysis

October 31, 2025The ribbon slitting machine is a key equipment in the thermal transfer printing industry chain, mainly used to cut the large width Read More

Read More